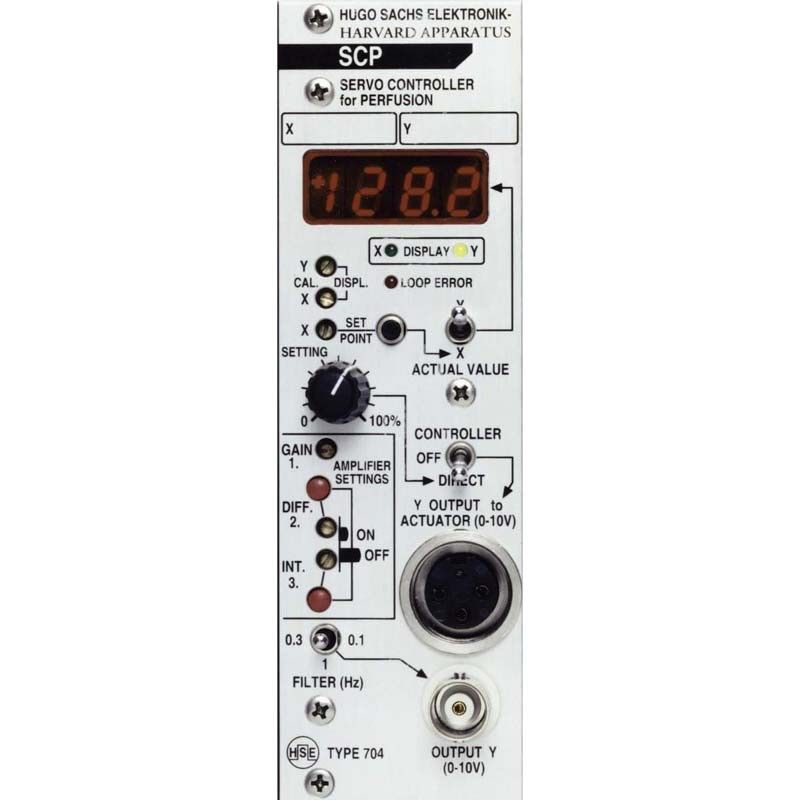

PLUGSYS Servo Controller Module (SCP) for Perfusion Pressure Regulation and Indirect Flow Measurement

The PLUGSYS SCP module is a PID pressure controller intended for perfusion control of isolated organ perfusions using a peristaltic pump. It works together with PLUGSYS bridge amplifiers TAM-A and TAM-D. The modules must be built into a housing which provides the power for the modules.

The SCP controls perfusion under constant flow or constant pressure with just one switch. It is also used for an easy and inexpensive flow measurement since the controller also calculates the perfusion flow from pump speed.

Connection cables are available to connect the SCP to different peristaltic pump.

The Servo Controller for Perfusion (SCP) module is used for perfusion of isolated organs by controlling the speed of a peristaltic pump. It is a PID controller which operates to maintain perfusion either at constant perfusion pressure or at constant perfusion flow. It also calculates the perfusion flow, acts as inexpensive flowmeter (also called indirect flow measurement vs the direct method using ultrasound transit time technology).

For a functioning system the following additional items are required:

- Measuring system with transducer and amplifier for perfusion pressure

- Pump suitable for external control (analog input 0 to 5 or 0 to 10 V) and providing the appropriate pumping rate

- Suitable pump tubing

- Connection cable to selected peristaltic pump

- PLUGSYS TAM-A or TAM-D module

- PLUGSYS housing, Type 601, 603 or 607

The SCP is supplied with a connection cable to a Reglo roller pump (73-4618). Other cables can be substituted and are available on request.

Function

The built-in PID controller is used for controlling the connected peristaltic pump speed. Higher speed leads to a higher pressure in the perfused organ

In constant flow perfusion (DIRECT MODE) the SCP controls the pump speed. More speed more flow. Flow runs linear to pump speed.

In constant pressure mode the user can define a SET POINT, which is the desired pressure the organ should be perfused with. As soon you switch to the CONTROLLER mode the PID controller adjusts the pump speed so that after a few seconds the SET POINT pressure is reached and held on a constant level. If the pressure is below the SET POINT, the controller speeds up the pump. If the pressure is above the SET POINT the controller speeds down the pump. This control is running all the time in a closed loop.

Since the delivered flow rate in ml/min is running linear to the pump speed, the SCP module is able to calculate and display the flow rate directly from the pump speed. Thus the SCP is also a flowmeter. This is called indirect flow measurement because the flow is not directly measured but instead calculated. (Note: Direct flow measurement is accomplished with the PLUGSYS TTFM-2 module.)

The SCP also has an analog output (0 to 10 V) which corresponds to the pump speed. This output can be used for continuous flow recording using a PC-based Data Acquisition System

| Accessories | Operating Instructions, Screwdriver, Output Cable to Pump |

| Actual Value Input | 0 - 10 V via System Bus |

| Ambient Conditions | Laboratory Indoors |

| Connector | DIN 41612, 96-pin VG |

| Construction | Plug-in Module for a PLUGSYS |

| Control Gain | 1 - 50, Adjustable |

| Control Voltage | 0 - 10 V to Operate the Pump |

| Derivative Factor | 0.1 - 100, Adjustable |

| Description | Servo Controller for Perfusion (SCP) Type 704 |

| Digital Indication | Range -1999 to +1999, Selectable for Actual Value, Setpoint, or Control Output Signal |

| Function | Electronic PID Controller for Physiological and Pharmacological Research |

| Integral Factor | 0.05 - 10, Adjustable |

| PLUGSYS Width* | 2 slot units |

| Power Supply | 5 V, 0.3 A from PLUGSYS |

| Recorder Output | 0 - 10 V, BNC Socket |

| Setpoint | 0 - 5 V, Adjustable |

| Weight (Metric) | 0.3 kg |